Bambu Lab H2S 3D Printer | 340 x 320 x 340 mm³

- 340*320*340 mm³ Print Volume

- Multi-color 3D Printing

- Closed-loop Servo Motor Extruder

- Optional 10W Laser and Cutting Module

- 5μm Resolution Optical Motion Calibration

- 350°C Nozzle & 65°C Active Chamber Heating

- Full Filament Path AI Detection

- Voltage Range: 100-120 V

₹145,000.00 – ₹250,000.00Price range: ₹145,000.00 through ₹250,000.00 Including Tax

Fast Shipping

Secure Payment

Tracking Updates

Best Prices

Chat Support

In Stock Alert

Payment Methods:

Bambu Lab H2S

Your Personal Manufacturing Hub

AI Detection

23 Sensors & 3 Cameras

65 °C

Active Heated Chamber

10W 455nm

Laser Cutting

Up to 30%

Faster Print Speed

Auto Venting

Filament Drying

340×320×340

mm³ Large Volume

Your Go-To

Personal Manufacturing Hub

Accuracy That Works for You

Correct Mechanical Deviations

Even the printer comes out of the factory with superb accuracy, mechanical wear and variances over time are inevitable—but now, first time in the industry, there’s a solution.With the Vision Encoder⁽¹⁾, the H2S achieves distance-independent motion accuracy under 50 μm—thinner than a human hair. During calibration, it automatically compensates for mechanical drift, ensuring consistent precision and peak performance over time.

One Print. Perfect Fit.

Bambu Lab's Auto Hole/Contour Compensation⁽²⁾ minimizes printing tolerances, delivering machine-shop-level precision for hole dimensions. Design fit-critical parts with confidence—integrate shafts, bearings, and fasteners without trial and error. Post-print assembly has never been easier.

Ready for Engineering Filaments

Featuring a 350 °C hotend and a 65 °C actively heated chamber, it supports the entire Bambu filament lineup—from PLA and PETG to PC and PPA. With closed-loop fan control and precise thermal management, the H2S minimizes warping and deformation while improving layer adhesion. Build large, high-performance parts that are as functional as they are strong.

Even Surfaces, Crisp Edges

H2S uses both the sensing capability of its servo motor on the extruder and the high-resolution eddy current sensors on the nozzle to precisely control extrusion by measuring nozzle pressure and calibrating PA parameters for each filament, improving surface smoothness and edge sharpness.

Precision in Motion

Active Vibration Compensation neutralizes micro-vibrations and resonance in real time, enabling premium print quality at higher speeds.er title text example

Print Functional Designs

Intelligence That’s Got Your Back

20,000 Checks Per Second

Closed-Loop Feedback, Real-Time Control

Bambu Lab’s proprietary PMSM servo system enables 20 kHz resistance and position sampling to dynamically modulate electromagnetic torque vectors. It stabilizes extrusion and actively detects grinding⁽³⁾ or clogs in real time.

23 Sensors + 3 Cameras

Each Potential Risk Has Its Own Detector

Pre-Flight Checklist by AI

Prior to each operational cycle, the H2S vision system initiates a comprehensive pre-flight checklist: Chamber Integrity Scan – Detects debris across the entire print surface. Hardware Configuration Audit – Instantly identifies build plate properties.

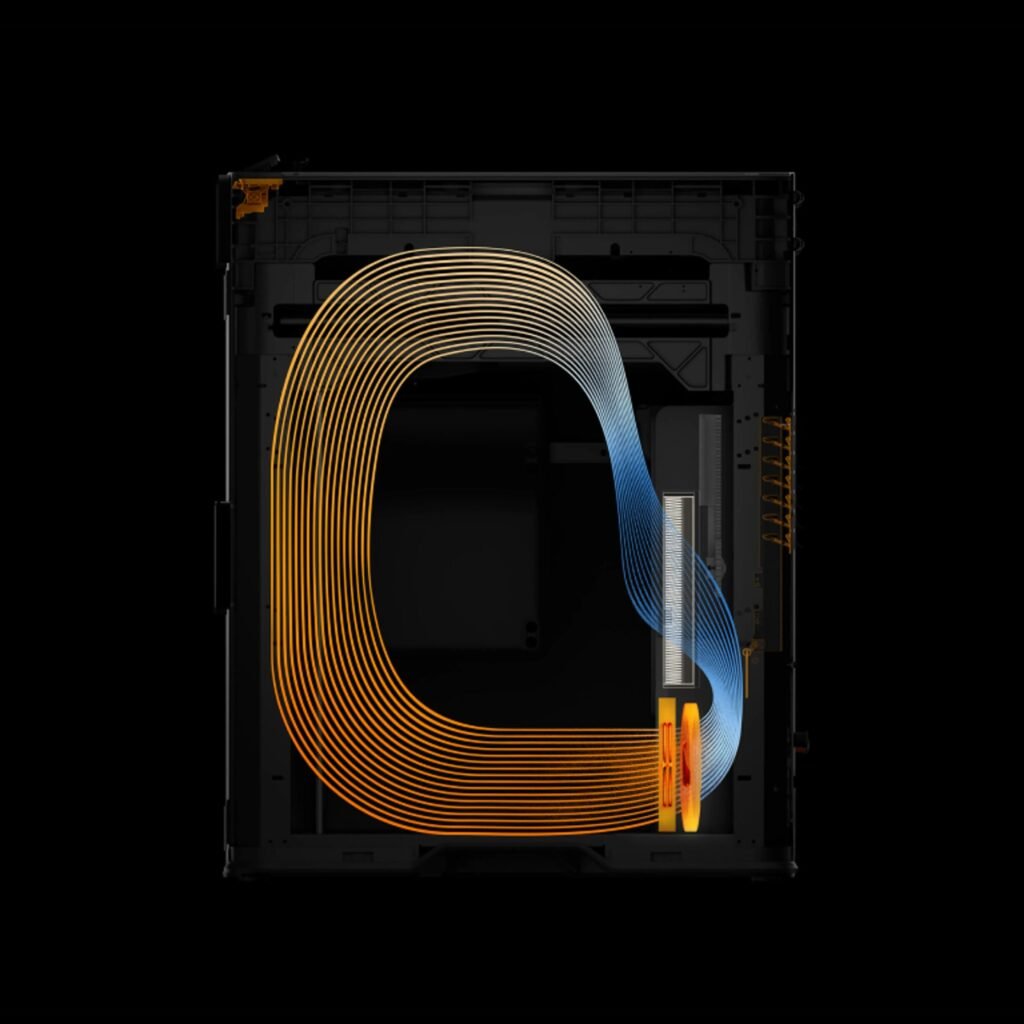

Flap Switch Airflow & Filtration System

3D Printing & Laser Cutting. 3 Modes, All-in-One

High-Temp Printing

Chamber sealed. Internal air recirculates through the Air Filter and the heater to stabilize high-temp conditions. Print large engineering parts without warping.

Low-Temp Printing

Top Vent opens to bring in cool air, while maintaining a filtered exhaust⁽⁴⁾. Print PLA and PETG without opening the door, and handle overhangs and bridging with ease.

Laser Cutting/Engraving

Top Vent and Filter Switch Flap open. Fumes are channeled efficiently to the ventilation system, keeping your workspace safe and clean.

Bigger. Faster. Better.

Maximum Volume. Maximum Productivity.

With a build volume of 340×320×340 mm³, the H2S offers the largest print space among all Bambu Lab printers. Your Vision. Fully Realized in One Print.

Top Speed. More Reliable Than Ever.

Bambu Lab’s proprietary PMSM⁽⁵⁾ servo extrusion system delivers 67% more extrusion force, providing solid support to high flow⁽⁶⁾ printing. Paired with up to 1000 mm/s toolhead speed and up to 20,000 mm/s² acceleration, your H2S can finally go full throttle—cutting your printing time by up to 30%⁽⁷⁾—while maintaining top-tier quality.

12.3% Faster Than X1C

11.2% Faster Than X1C

22.2% Faster Than X1C

Not a Toolkit.

A Production-Ready Platform.

Reviews

There are no reviews yet.